Service and Engineering Consulting without compromise:

Your reliable partner

Are you looking for a partner in the field of engineering services or engineering consulting? Your search has now come to an end!

We offer holistic engineering services and consulting in the areas of design, drafting, product development and prototyping. With our broad expertise and many years of experience, we support you in the implementation of your projects and accompany you from the idea to the finished product. Our services include but are not limited to:

- Design work and welding support

- Engineering Consulting

- CAD drawings

- Digitization of old drawings

- Prototype construction and product development in our own test workshop

With our wide network of selected suppliers, we can guarantee you high-quality manufacturing solutions Made in Germany. You will benefit from optimal delivery times and a competitive price-performance ratio.

Expertise in various industries:

- Metal construction, stainless steel processing, welding engineering, machining technology

- Bolted joint connections

- Plastics Technology

- Pipeline construction, pressure vessel construction and sealing technology

- Processing technology

We look forward to assisting you in the realization of your projects.

How it works

Carlo Borns

Managing Director

CB-Industrials GmbH

Request a non-binding offer

Insights into our work

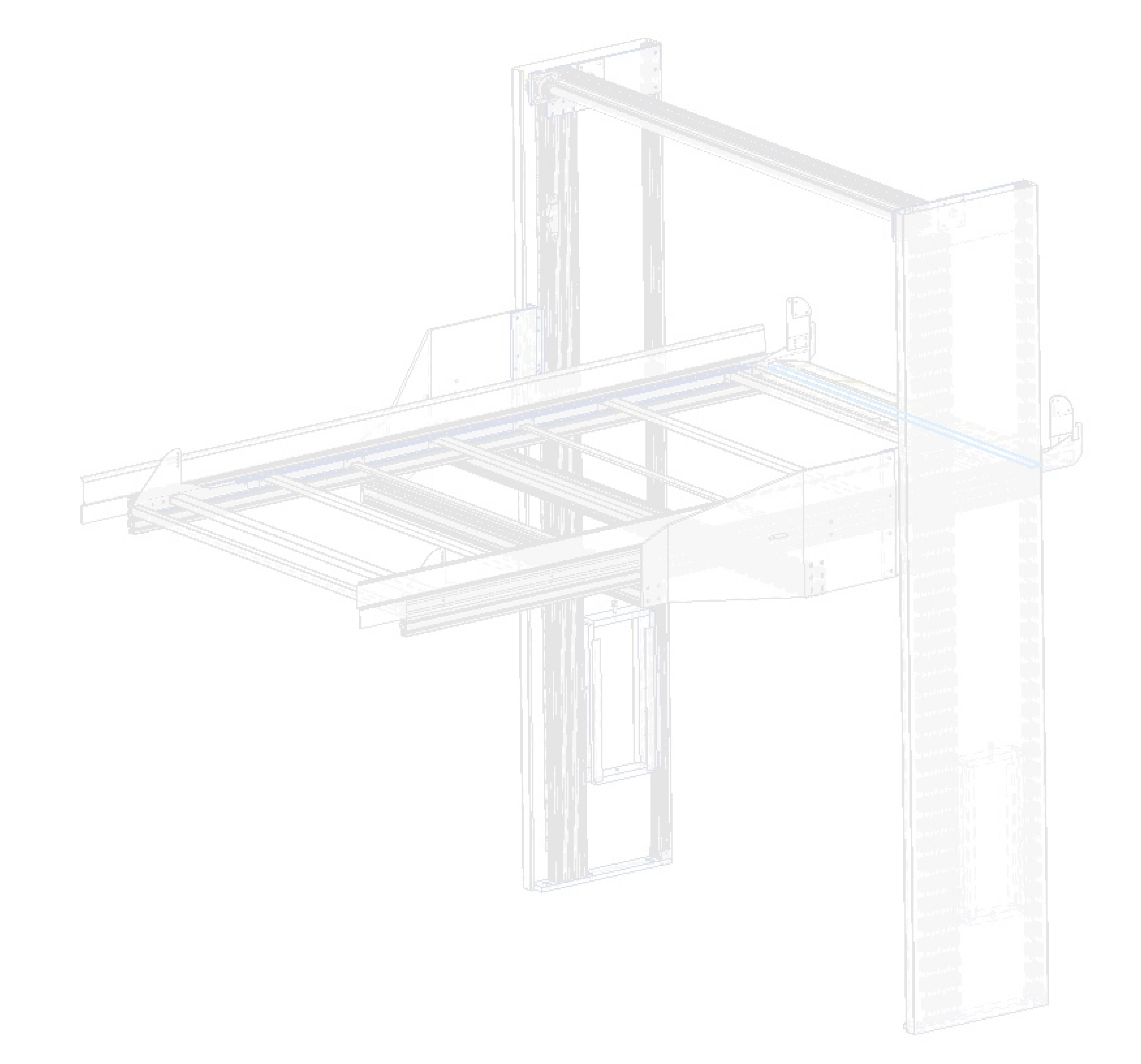

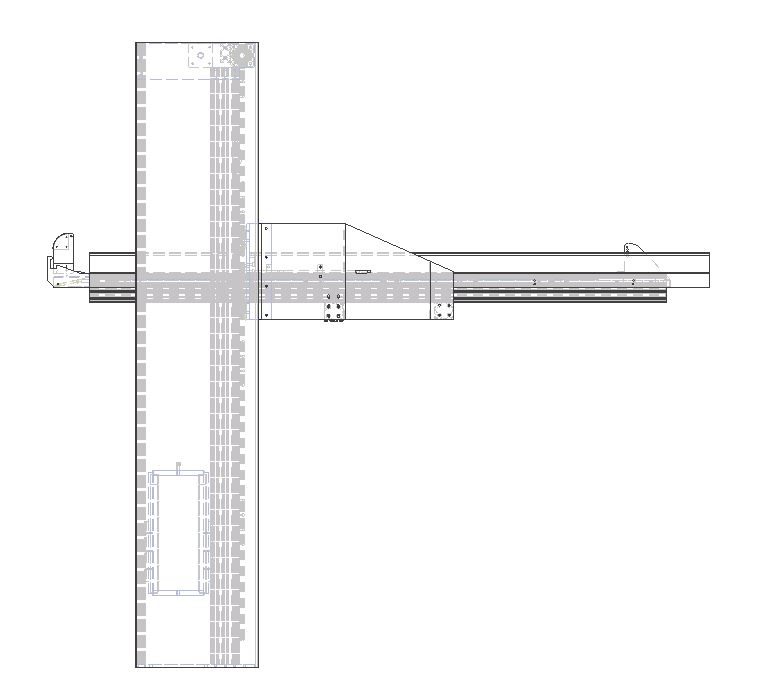

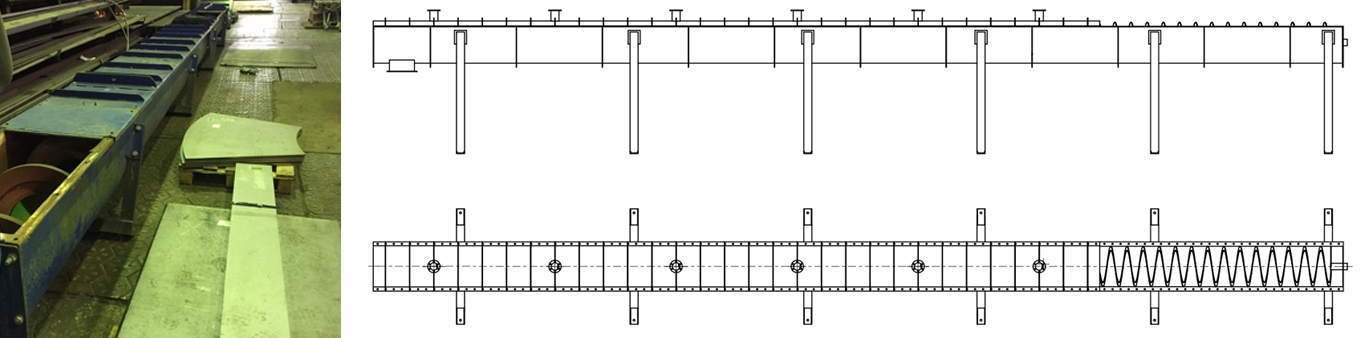

Development, design and construction of a chemical-physical treatment plant for lithium secondary batteries (accumulators)

In the end, the plant consisted of a 12-meter-long liquid-filled spiral conveyor, which played a key role in the processing of lithium batteries/accumulators. Suction nozzles were installed along the entire length of the screw conveyor and also on the feed hoppers of the shredding units. In this way, we ensured that the reactions of the batteries would accumulate under controlled conditions.

To avoid overheating of the batteries, we planned a spraying system with special nozzle heads, which emitted a fine spray onto the batteries. In this way, the temperatures in the plant could be controlled.

Another important part of the plant was two four-shaft shredders of different sizes. Both shredders, actually designed for other purposes, offered high and reliable shredding performance.

Downstream filtration technology to separate the carbon matrix was also part of the final setup. In this way, it was achieved that the plant complied with environmental regulations and all emissions and dust particles could be filtered.

Overall, the project was a great success.

We will gladly analyze how your project can best be realized

in a free consultation.

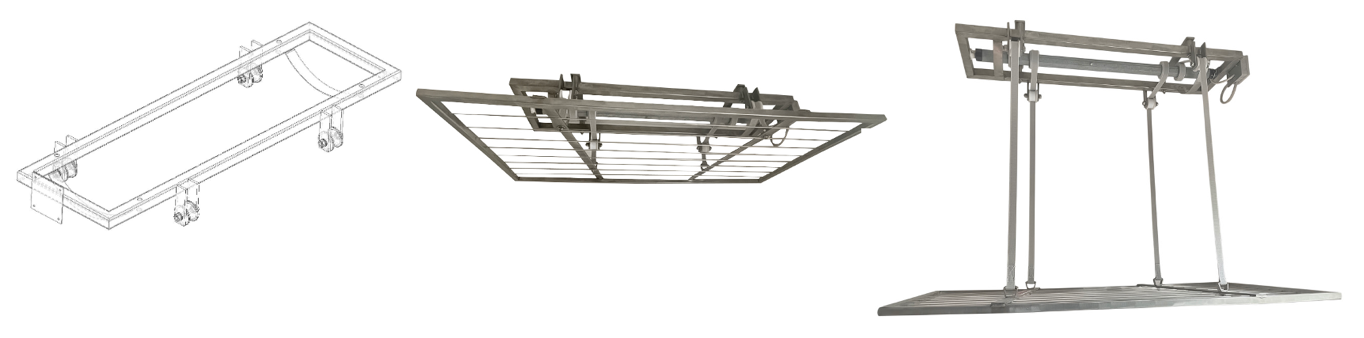

Design and manufacture of an industrial drying rack (laundry elevator) with self-centering guide

The project included the design and manufacture of an automatic drying rack. The aim was to develop an electrically movable, low-maintenance system that operates self-supporting without rail guides and has a load capacity of 25 kg. The spindle dimensions should be 2,000 mm x 1,200 mm.

Particular focus was placed on optimal space utilization through a very low overall height.

The welding process used for the production was TIG. The material chosen is a corrosion-resistant high-alloy chromium-nickel steel. The guide rollers were machined entirely from PTFE so that ball bearings could be dispensed with. The guidance of the belts was designed so that the winding is self-centering at all times.

The result was an automatic drying rack that effectively and efficiently supports the drying process and, thanks to its space-saving design, allows optimum use of space.

We will gladly analyze how your project can best be realized

in a free consultation